Ahmed Elmalla - Your Dedicated Computer Science Tutor | Learn with Kemo

Ahmed Elmalla - Your Dedicated Computer Science Tutor | Learn with Kemo Portfolio

Understanding Machine Vision: Key Applications in Modern Manufacturing

Understanding Machine Vision: Applications and Advancements in Manufacturing

What Is Machine Vision?

Machine vision is a technology that combines computer software, hardware, cameras, and lighting to capture images of products during manufacturing. By analyzing these images, machine vision systems can detect defects, ensuring that only high-quality products reach consumers. This technology also helps manufacturers improve processes, reduce costs, and increase efficiency.

While machine vision began to emerge in the early 1980s for quality control, early systems were complex, expensive, and limited in performance. However, advancements in microprocessor and software technologies have made modern machine vision systems more powerful, cost-effective, and easier to implement. Today, machine vision is a key component of process control, helping manufacturers enhance product quality and boost productivity.

Applications of Machine Vision Systems

Machine vision applications are typically divided into three categories:

- Process Control

- Quality Control

- Industrial Applications (e.g., traffic control, gas leak detection)

In modern industry, human inspections often fall short in terms of speed, accuracy, and consistency. Humans can get fatigued, make errors, and apply subjective criteria. In contrast, machine vision systems offer precise, consistent measurements aligned with production standards. These advantages have driven widespread adoption of machine vision across industries globally.

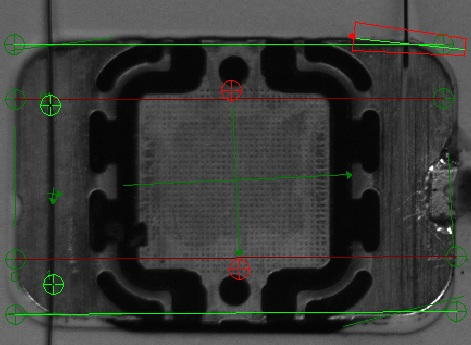

The image above is for an RFID chip inspected by a smart camera after the bonding process.

Example Applications in Manufacturing:

- Inspection of optical quality in TV and computer screens

- Quality control of automotive paint during manufacturing

- Inspection of banknotes during printing

- Testing of electronic circuits

- Verifying pharmaceutical packaging completeness

- Ensuring proper bottle filling in production lines

- Detecting defects in ceramic tiles

The image above is for a micron precision vision system that was integrated into the German eID production line to locate the the 100 micron RFID antenna wire before initiate the bonding process.

The image above is for Safety Syringe Needle Inspection station built for a chinese customer.

Real-World Machine Vision Solutions

-

RFID Chip Bonding Inspection:

The image above shows an RFID chip inspected by a smart camera following the bonding process, ensuring quality and alignment. -

Precision Vision System for eID Production Lines:

The image illustrates a micron-precision vision system integrated into a German eID production line. This system locates a 100-micron RFID antenna wire before initiating the bonding process. -

Needle Inspection Module for B|Braun:

Shown above is a safety syringe needle inspection station developed for a Chinese customer, demonstrating the system’s ability to detect defects with high accuracy. -

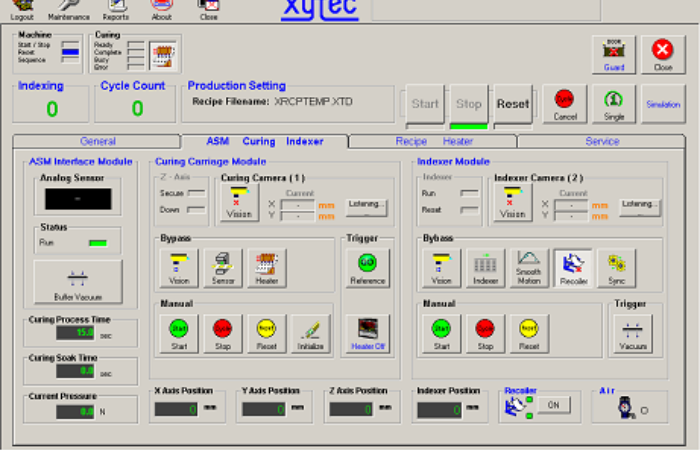

PC-Based Production Line Control Software:

The image above features PC-based software designed to control production lines, interfacing with vision systems and PLCs to ensure seamless operation.

The above image is for a PC-Based software written to control the production line and communicate with vision systems and PLC.

Experience in Machine Vision System Development

I have built numerous machine vision systems for German and Swiss machinery manufacturers in Malaysia. My expertise involves using a combination of smart cameras and vision libraries, such as Vision Pro from Cognex, to architect reliable and efficient systems for various industrial applications.