Ahmed Elmalla - Your Dedicated Computer Science Tutor | Learn with Kemo

Ahmed Elmalla - Your Dedicated Computer Science Tutor | Learn with Kemo Portfolio

Optimizing Machine Automation: From PC Control to Multi-Axis Motion Systems in Industrial Automation

Optimizing Machine Automation: From PC-Based Control to Multi-Axis Motion Controllers

I was one of the few programmers in my company who specialized in building PC-based machine control software. While others primarily focused on PLC-based control for machine sequencing, I expanded my skill set over time to include programming for various PLC types. I also learned how to shift portions of the control sequence to hardware devices like motion controller cards, improving efficiency and flexibility.

Key Concepts in Machine Automation:

1. Calculating Machine Throughput:

Machine throughput directly impacts process efficiency—the faster a product is produced, the better. Throughput is calculated using the formula:

TH=IT\text{TH} = \frac{I}{T}TH=TI

Where:

- TH = Throughput

- I = Number of items produced

- T = Time taken

This formula is critical in optimizing production processes.

2. What Is PC-Based Automation?

PC-based automation involves using software on Windows PCs to control real-time applications written in languages like C#, C++, and .NET. These applications handle tasks such as motion control and machine vision in industrial settings, offering more flexibility than traditional PLC systems.

3. What Is a Multi-Axis Motion Controller?

A multi-axis motion controller is designed to manage the movement of automated systems across multiple axes. These controllers are essential for smart, discrete designs that involve synchronized, multi-axis operations, enhancing overall precision and efficiency in automated processes.

4. What Is Visual Basic (VB) Used For?

Visual Basic (VB) is an event-driven programming language from Microsoft that features a graphical user interface (GUI) for ease of use. In industrial applications, VB is commonly used for sequencing machines, especially in systems with fewer servo motors. The drag-and-drop environment allows for rapid development and customization.

Real-World Application in Industrial Automation

Back in 2006, we used the XP Embedded OS on industrial PCs for all RFID machinery at Xytec in Malaysia. In some machines, VB was the primary language used for machine sequencing, especially for setups with fewer than eight servo motors.

One of the key techniques for improving machine cycle time is to analyze and measure idle times within the production process. By designing control sequences to utilize these idle times for long-duration tasks and running machine tasks in parallel using smart cards (like Galil motion controllers) and smart cameras, overall efficiency can be significantly improved. Synchronization between these parallel tasks is achieved using sensors or flags.

Fine-Tuning Software for High Throughput

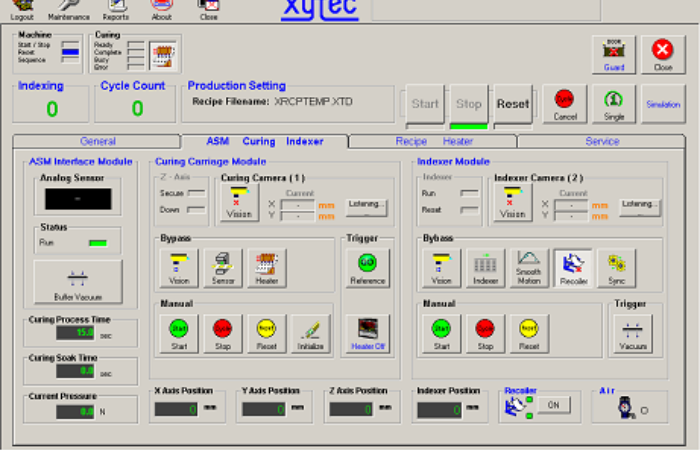

The image above shows a machine equipped with multiple smart cameras and over seven motors. The system was programmed using a combination of VB and Galil programming languages, resulting in higher throughput than a comparable PLC-based machine. One challenge in using VB is its timer function, which has a 15 ms accuracy limitation. I addressed this by offloading substantial portions of control code to the motion controller, which allowed my machines to outperform traditional PLC-controlled systems.

SMARTRAC and RFID Manufacturing

SMARTRAC, a leading provider of inlays for contactless credit cards (ePayment) and ePassports, was founded in 2000 and is headquartered in Amsterdam. The company’s main production and R&D center is in Bangkok, with additional sales offices in Stuttgart and Singapore. Through an exclusive partnership with Xytec Solutions in Malaysia, where SMARTRAC holds a 30% stake, they have access to proprietary manufacturing equipment that sets them apart in the industry.