Building machine Vision Systems

What Is Machine Vision?

A machine vision system consists of computer software and hardware working together with cameras and lighting to capture images of products as they are being manufactured. This prevents defective products from being shipped to consumers and helps manufacturers improve their processes and reduce costs. Commercial use of machine vision technology for manufacturing quality control began to emerge in the early 1980s. However, machine vision systems at that time were complex to program and maintain, difficult to install, limited in performance and not cost-effective. Through advances in microprocessor and software technologies, these barriers have been removed, enabling machine vision to emerge as a powerful process control technology that allows manufacturers to improve quality and increase productivity.

Machine vision applications are divided into three main categories:

• Process Control

• Quality Control

• Industrial applications (eg traffic control, Gas leak detection)

Inspections carried out by humans, often can not meet the requirements of modern industry with regard to production rate, product quality and production costs. Humans get tired, make mistakes and the criteria for inspections are inevitably subjective. In some cases, it is not humanly possible to accomplish the task of inspection due to environmental conditions. The cameras and systems that comprise a machine vision system, by contrast, carry out measurements with accuracy and at a steady rate established by the production process itself. These advantages have led to a growing acceptance of machine vision by the industry across the world.

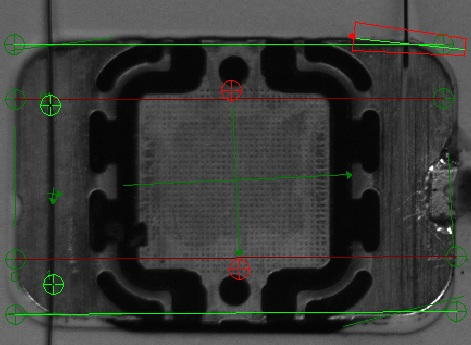

The image above is for an RFID chip inspected by a smart camera after the bonding process.

Applications of this technology in facilities around the world include:

• Inspection of the optical quality of the TV and computer screens

• Inspection of the quality of the paint during the car manufacture

• Inspection of banknotes during printing

• Testing of electronic circuits

• Check pharmaceutical packages completeness

• Inspection to ensure that bottles are properly filled

• Checking for defects in tiles in the ceramic industry

The image above is for a micron precision vision system that was integrated into the German eID production line to locate the the 100 micron RFID antenna wire before initiate the bonding process.

The image above is for Safety Syringe Needle Inspection station built for a chinese customer.

The above image is for a PC-Based software written to control the production line and communicate with vision systems and PLC.

I built many machine vision systems for German and Swiss machinery builders in Malaysia. I used a combination of Smart cameras and Vision libraries ex. Vision Pro from Cognex to architect those systems.

.png)

.png)

.png)